Raj Talluri explains how the company’s breakthrough AI-1 silicon anode battery platform delivers 1,000+ cycles while enabling all-day power for AI-intensive applications.

By Ray Chalmers, Sep 10, 2025

In July 2025, Enovix Corporation announced the launch of its AI-1 battery platform, a silicon-anode design with many advanced features to power AI functionalities on new smartphones and other smart devices. Raj Talluri, Enovix president, recently sat down with Battery Technology to discuss market reactions, interest from other sectors, and scale-up efforts.

Any notable reactions to the AI-1 announcement you can share?

Enovix President Raj Talluri: In August, I was in China visiting customers. The reaction has been fantastic. The key attribute of the AI-1 is that it is the first 100% silicon anode able to push energy density beyond 900 watt-hours per liter (Wh/L), the highest commercially available. That’s in connection with the ability to charge really fast. We recently announced independent testing results of the AI-1 achieving a 20 percent charge in 3.8 minutes, 50% in 12.3 minutes, and 100% in 39.5 minutes, in addition to going more than 1,000 cycles in standard smartphone usage.

Enovix President Raj Talluri; the AI-1 silicon-anode battery.

Another very important thing is that, because of the unique architecture, the battery doesn’t swell. Most lithium-ion batteries, if you cycle them for a long time they swell quite a bit at the end of life. What some OEMs do is leave space in their phones or other consumer products so swelling doesn’t cause any damage. AI-1 swells very little at the end of its cycle, meaning customers can save space and perhaps use an even larger battery in their design to achieve much higher energy density.

Related:Silicon-Anode Batteries Redefine AI Smartphone Performance

We are providing samples to a few smartphone OEMs, and while testing will take a number of months, initial feedback is very positive. Due to AI applications, OEMs are finding that their phones don’t last an entire day. ChatGPT for search, for example, causes concern because it takes so much of the battery, making a higher-density battery very attractive.

Use cases beyond smartphones

Is this attracting attention from other market segments?

Talluri: Manufacturers of smart eyewear (smart glasses) are also showing interest. In my mind, this is a very interesting space. There are models with AR and VR (augmented reality/virtual reality) capabilities that provide depth to product use, and then there are models with cameras, audio, and more advanced features. They look like very fashionable sunglasses, but with the ability to watch video, listen to music, and interact intelligently with the tasks at hand. When I was in China, a gentleman with smart glasses was speaking to me in Chinese, and my smartphone was providing translation in real time. When I replied in English, his glasses would display my remarks in Chinese. Whether for business travel or personal use, the applications and potential are amazing on many levels.

Related:Laser Cutting Improves Battery Manufacturing at Enovix

So, batteries are no longer a limiting factor?

The battery makes the product. That’s what we’re finding. Without the battery, the product doesn’t exist. Glasses with the advanced applications we’re talking about currently last only four or five hours. AI is shifting the mobile user interface from taps and clicks to voice commands and gestures. The value of these efficiencies will be undercut by battery constraints, forcing users to remain tethered to power outlets or lug around external battery packs.

This is a problem that not enough people are talking about. We face a tradeoff that no one wants: whether to harness AI’s full capabilities or preserve battery life.

“This is a problem that not enough people are talking about. We face a tradeoff that no one wants: whether to harness AI’s full capabilities or preserve battery life.”

The consequences are even more severe for professionals and businesses that rely on AI-driven tools. Mobile workers who depend on AI assistance for tasks such as real-time translation, automated data analysis, and virtual meetings will be inconvenienced by devices that can’t sustain a full day’s work on a single charge. In industries such as healthcare, logistics, and emergency response — where real-time AI-powered decision-making is already crucial — battery limitations could have serious operational consequences.

Related:Are Batteries the Barrier to Better Consumer Devices?

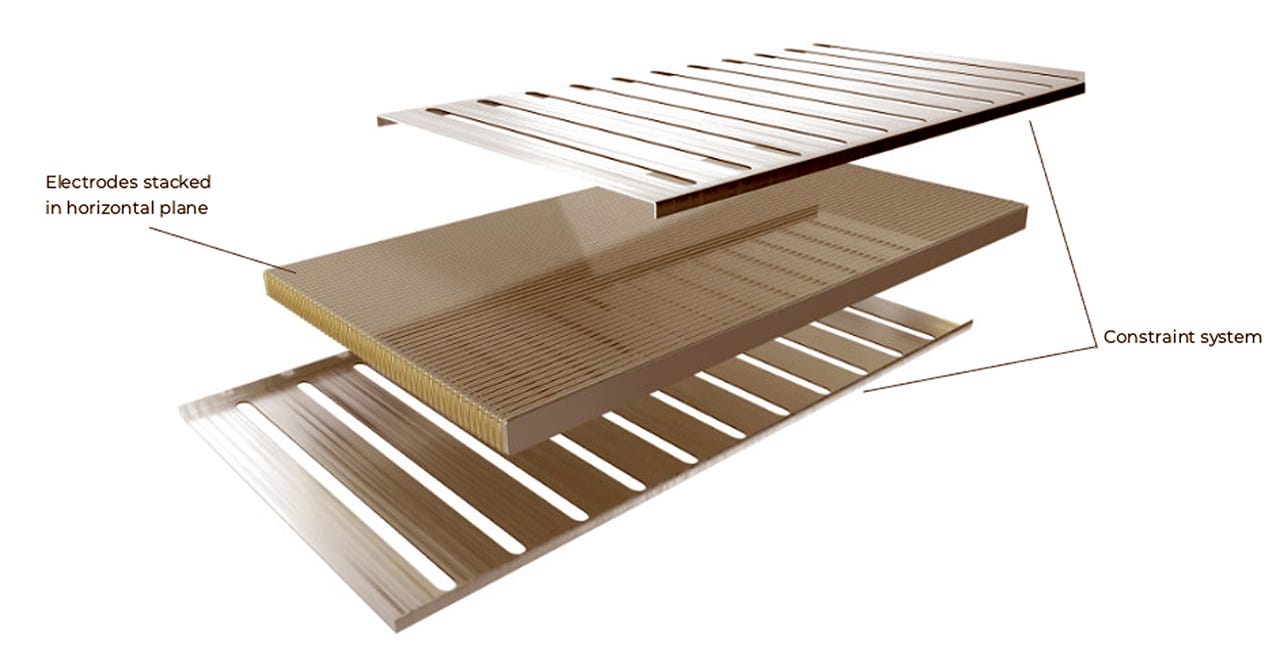

AI-1 has more than 200 architecture-specific patents supporting its performance. To get more energy density in the battery, you need to replace the graphite with silicon, and silicon swells whether we like it or not. To stop it from swelling, our architecture and the patents we have on it cover “dicing” the anodes and cathodes, stacking them, and adding a constraint to hold the construction in place. This makes things very safe. I got feedback from customers saying the Enovix battery was the safest power cell they had ever tested. Having a higher energy-density battery makes safety even more important.

Illustration of the basic Enovix cell structure (2023). Credit: Enovix

Also, since no one until now has commercialized a 100% silicon anode battery, the electrolyte and its electrochemistry that can accomplish long cycle life and fast charging are also unique. We’ve done a lot of work on that.

Bespoke battery production equipment

There are billions of smartphones and other smart devices. What does this entail about Enovix battery production?

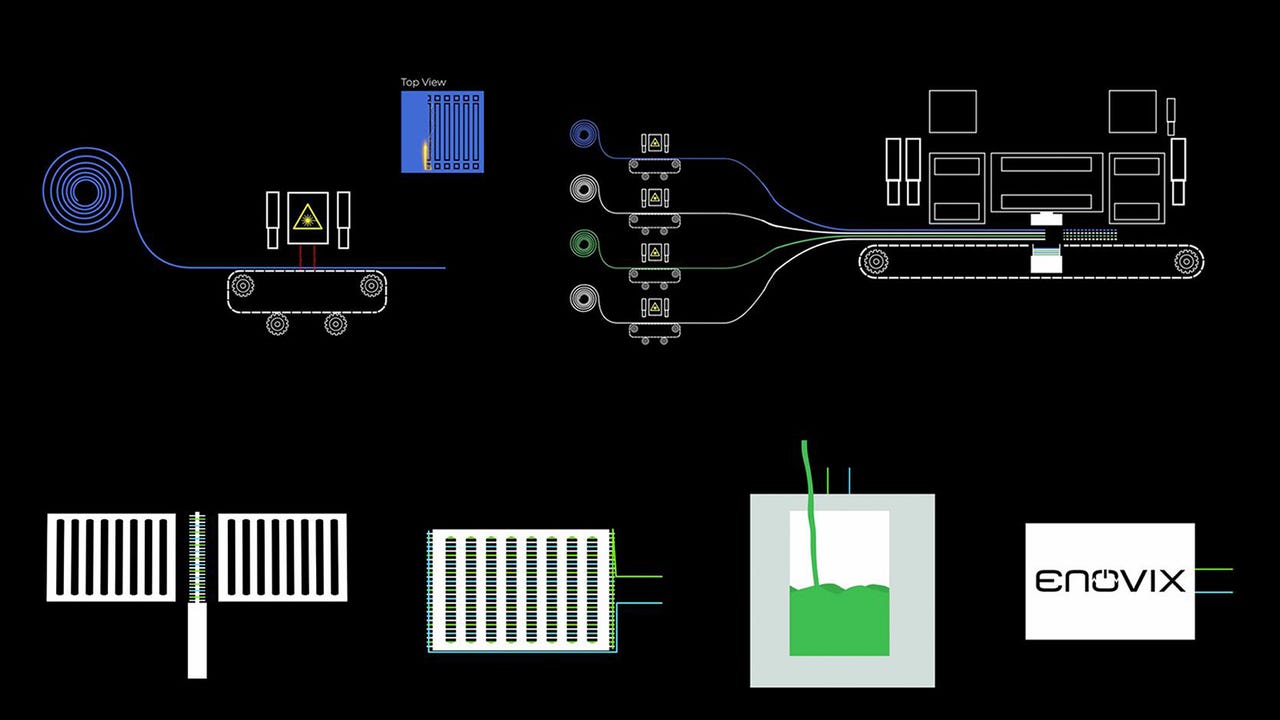

Talluri: The AI-1 battery is manufactured on machines we designed and built. These are not machines you can just source and buy. They are bespoke equipment not available through conventional suppliers. There is some standard equipment, but the majority of the production process, the laser-based dicing, the component stacking, and other constraint building, takes place on machines we build ourselves.

The AI-1 custom laser slitting, stacking, and constraining production process. Credit: Enovix.

The samples we are currently supplying customers come from our Fab 2 high-volume manufacturing facility in Malaysia that opened in 2024. We are currently scheduling additional high-volume manufacturing lines in Malaysia to be operational by 2026 to handle the expected demand.

Coming soon: AI-2

And the future?

Moving forward, any applications needing a high degree of AI functionality are targets for AI-1, such as hand-held terminals, industrial robotics, and more.

We also recently announced our new R&D Center of Excellence in Hyderabad, India, to accelerate the development of the second-generation battery platform AI-2 prototypes available later this year. The Hyderabad battery lab can produce about 2,600 coin and small pouch cell prototypes per year for fast, early, rapid materials evaluation. And the test area can test up to 750 small cells simultaneously. Integrating modeling, materials development, and rapid prototyping under one roof accelerates innovation, as has already been demonstrated on our AI-1 platform.

https://x.com/TESLAART3/status/1967749104693563861?t=wQq55gLvzKgydXvd0vb3Gg&s=19